Summary

Computer Vision powered by AI is transforming the AgriFood sector by bringing real-time visual intelligence to crop monitoring, quality control, and resource management. From flowering to fruit ripening, this technology enables producers to make smarter decisions based on accurate visual data, improving productivity, sustainability, and regulatory compliance.

Description

The AgriFood industry faces unique challenges: unpredictable crop yields, inefficient resource use, disconnected systems, and reliance on manual inspections. Computer Vision with AI addresses these issues by automating visual analysis across the entire value chain—from field to factory.

This no-code solution integrates seamlessly with ERP platforms, satellite imagery, sensors, and even WhatsApp-based advisory systems. It empowers cooperatives, producers, and agribusinesses to optimize harvest planning, resource allocation, and quality assurance.

Key Benefits:

- >90% accuracy in defect and crop stage detection.

- >90% reduction in labor costs for quality control.

- 90% real-time visibility and alerts

Applications in AgriFood

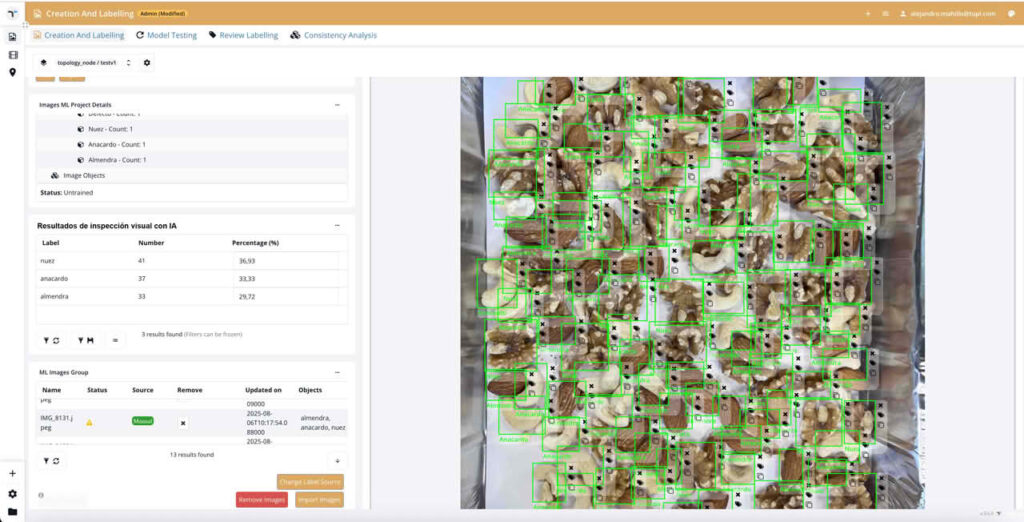

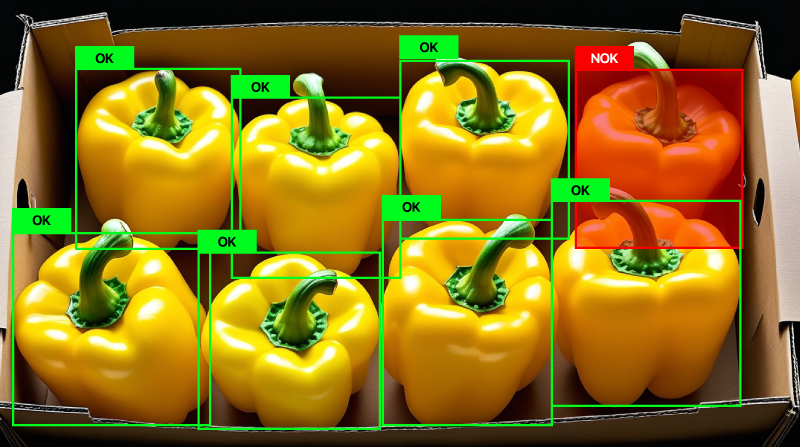

1. Automated Quality Control in Field and Factory

AI-driven vision systems inspect fresh produce, meat, and packaged goods for shape, color, size, and surface quality. This reduces reliance on skilled labor and ensures consistent product classification—even under variable lighting or positioning.

2. Precise Packaging Validation

The system verifies barcodes, expiration dates, batch numbers, and label alignment to prevent costly labeling errors and ensure food safety compliance.

3. Real-Time Defect Detection to Reduce Food Waste

Early identification of non-conforming items minimizes waste and rework, boosting line efficiency and supporting sustainability goals.

4. Crop Monitoring and Planning

AI vision identifies critical crop stages like flowering, fruit formation, and ripening. It also detects anomalies such as pest damage or irrigation issues, enabling proactive decision-making.

FAQs

What agrifood stages can be analyzed with AI-powered vision?

Do we need special cameras or hardware?

No. It works with standard camera feeds, mobile images, drones, or installed field cameras.

Can it integrate with our ERP or planning systems?

Yes. It syncs with agricultural ERPs and data platforms for automated work orders, production logs, and harvest planning.

How accurate is the detection?

The system offers over 90% accuracy in identifying crop stages and defects, ensuring data-driven decisions.

How do field technicians interact with the system?

They can receive alerts and send updates via WhatsApp or a mobile app—no new tools or technical skills required.

Explore this content with AI:

Table of Contents

Share this post