Summary

Computer Vision powered by AI is revolutionizing quality control in manufacturing. By automating defect detection in real time, it enhances precision, reduces waste, and minimizes human error. This no-code solution empowers non-experts to deploy models easily, streamlining operations without altering existing systems.

Description

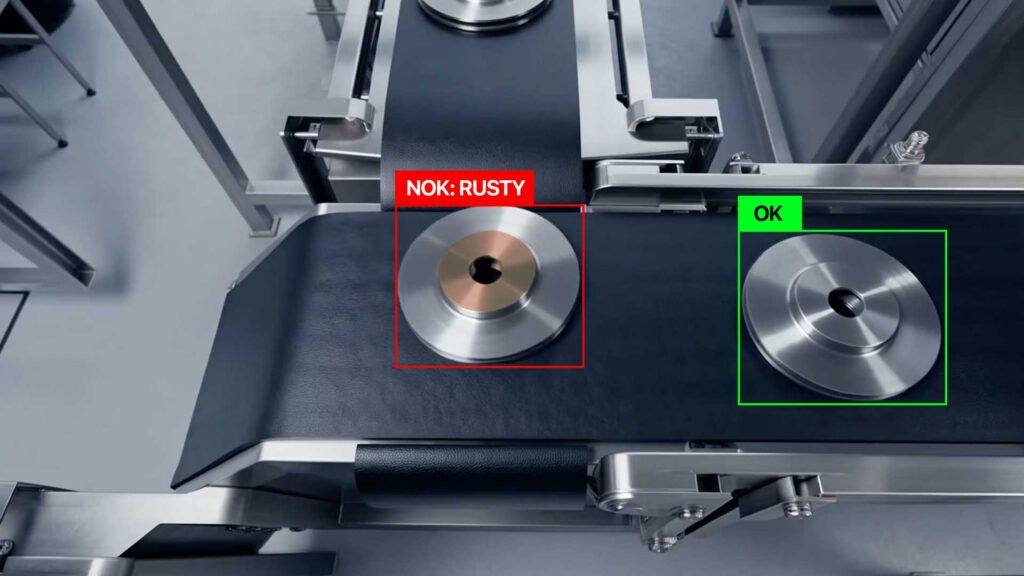

Modern manufacturing demands speed, accuracy, and consistency—especially in quality control. Traditional inspection methods often rely on manual labor, which can be inconsistent, costly, and prone to error. Computer Vision with AI addresses these challenges by automating visual inspections and enabling real-time defect detection.

This intelligent solution uses image analysis to identify anomalies such as cracks, misalignments, or incorrect labeling. It integrates seamlessly into production lines, offering centralized quality control without requiring changes to existing infrastructure.

Key benefits include:

- Over 90% defect detection accuracy

- More than 90% reduction in labor costs

- 90% real-time visibility and alerting

Applications in Manufacturing

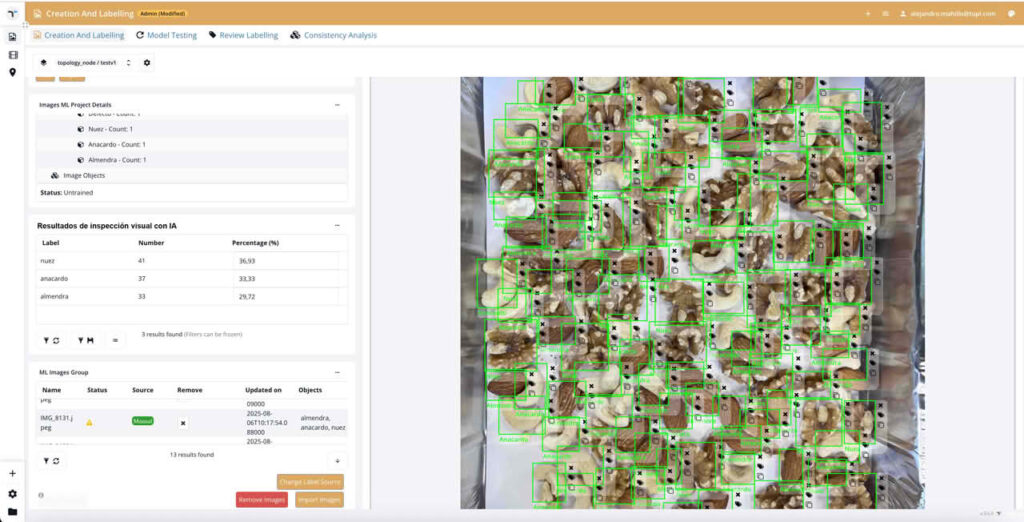

1. Automated Visual Inspection

Reduces human intervention in repetitive tasks. Operators can focus on higher-value activities while the system ensures consistent quality.

2. Packaging Validation

Verifies barcodes, expiration dates, and label placement with high precision, preventing costly errors and improving traceability.

3. Waste Reduction

Detects defects early in the process, minimizing material waste and energy consumption, supporting sustainability goals.

FAQs

What is Computer Vision with AI?

It’s a technology that uses cameras and AI algorithms to analyze visual data and detect defects or anomalies in real time.

Can it integrate with my current production line?

Yes. It works without requiring changes to existing systems, making implementation seamless.

What kind of defects can it detect?

It can identify surface defects, incorrect labeling, packaging errors, and more, depending on the training data.

How does it improve traceability?

By validating packaging and labeling in real time, it ensures accurate tracking throughout the supply chain.

Explore this content with AI:

Table of Contents

Share this post