Solutions

AI Factory Toolkit

Automate manufacturing processes in real-time.

It’s more than a MES!

Are you using all available factory data to improve your production processes?

The lack of data leverage results in missed opportunities for proactive issue identification and resolution. McKinsey Global Institute found that the use of advanced analytics in manufacturing could increase productivity by up to 30% and reduce maintenance costs by up to 20%.

How challenging is it to manage factory data dispersed across multiple systems?

- Limited scalability.

- High cost to maintain.

Have you successfully implemented MES in your factory?

The lack of MES implementation may result in challenges related to data management, resource allocation, and overall operational effectiveness.

According to Capgemini: “Though 76% of manufacturers either have a smart factory initiative that is ongoing or are working on formulating it, only 14% of companies are satisfied with their level of success.”

- Lack of adequate employee skills.

- Unrealistic expectations.

AI Factory Toolkit is more than a MES because it leverages workflows automation, scheduling optimization, resource allocation, and helps to minimize manual tasks and errors

What benefits can you expect from AI Factory Toolkit manufacturing automation software?

Accelerates

Factories' digital transformation

Total

Consistency

Real-Time

Data driven factory management

Empowers

Factory operators with AI

AI Factory Toolkit bridges the gap between the planning and execution stages of production

Centralized automated analytics and actions

- Centralized solution, works with any data source: ERP, Scada, Data bases, IOT devices and much more.

- Real-time prediction of abnormal behaviors: Operators, machines, material logistics, factory stock planning...

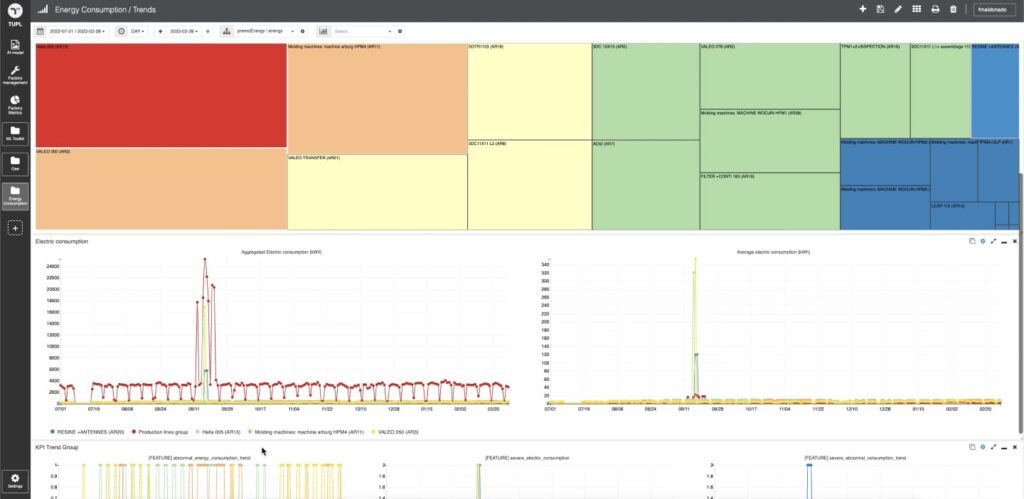

- High-value dashboarding to monitor KPIs and relevant features: Individual and aggregated statistics for every company level (company, factory, production line, station, device...)

- Automated actions based on AI prediction algorithms: Triggers factory actuators, automatic messages, reports...

Unlock your data's potential with TuplOS - the all-in-one MLOps no-code suite for hyperautomation

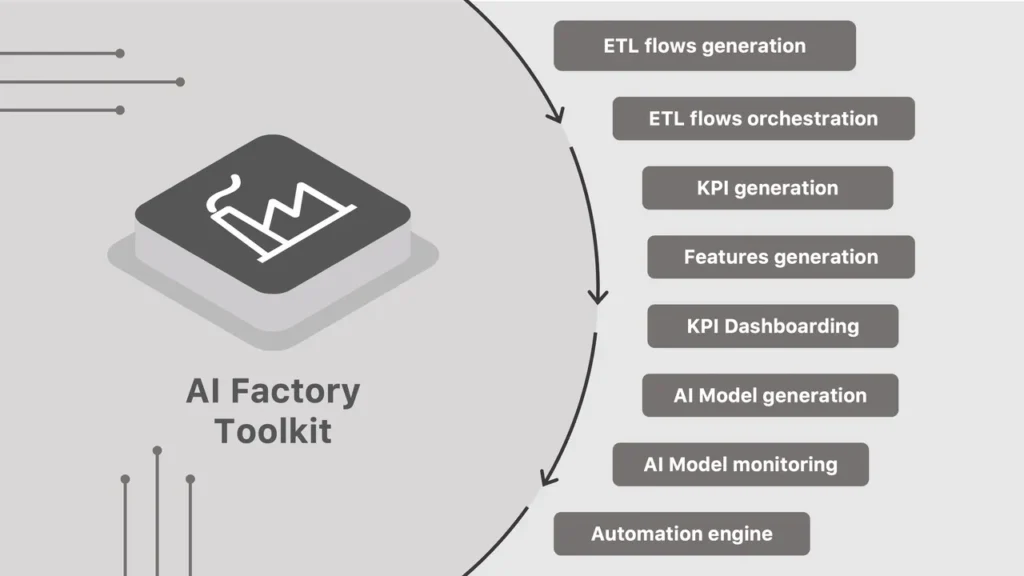

- Data Engineering: UI-based data management and transformation using Tupl tool Tupl Streams; KPI formulas with a low-code approach.

- Feature Engineering: UI-based feature formula generation, with types: Range, Time, and SQL features.

- ML Toolkit: creation of machine learning models in which the different ML algorithms are selected by clicking on available options; the training and usage of the model is done within the platform.

- Dashboarding: more than 100 widgets configurations and highly customizable views to analyze data trends.

- Automation Engine: UI-based automation template for open and closed loop real time actions taking place on AI models or rule models predictions.

Get a demo of AI Factory Toolkit today

Get started and request a demo to learn how AI Factory Toolkit can help you.

Frequently Asked Questions

Below you will find answers to the most common questions about AI Factory Toolkit.

How does AI Factory Toolkit MES work?

What kind of issues is AI Factory Toolkit trying to solve?

How does Tupl SaaS work?

AI Factory Toolkit SaaS is delivered in cloud service (e.g. AWS, Azure, etc.) and can also be deployed on-premises, in your private cloud, or data center.

Get started with a functional solution in operation within 2-3 weeks. Monthly subscription. No strings attached. Stop at any time.

Do I need an AI expert or developer staff?

No-code solutions for AI application development help manufacturers take advantage of this emerging technology without the need to hire technical specialists or investing significant time and capital.

Tupl’s software has a simple and intuitive user interface that enables existing personnel to build AI Smart Manufacturing applications for quality assurance in very little time with relatively small datasets and with no programming required.