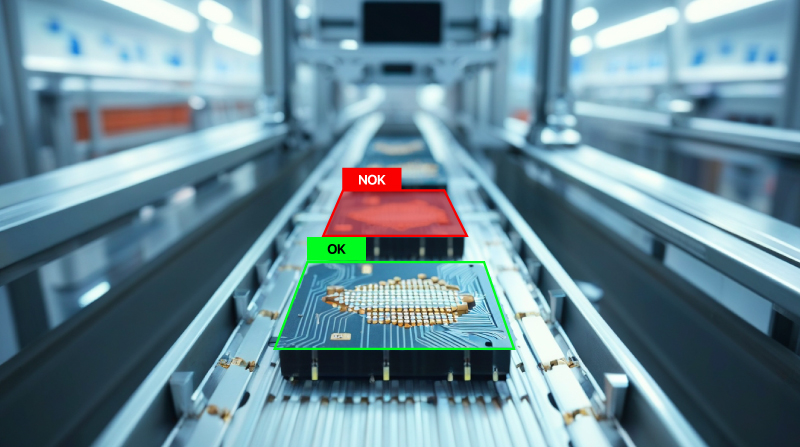

AI Computer Vision for

Quality Inspection

Automate defect detection with real-time visual intelligence.

Modern manufacturing demands speed, precision, and consistency, especially when it comes to quality control.

AI Computer Vision enables automated, real-time defect detection and classification in manufacturing.

This no-code solution empowers non-experts to train and deploy models easily, providing centralized quality control across production lines without requiring changes to existing systems.

Prevent Waste and Product Recalls

Human Error and Inconsistent Inspection

High Labor Costs

and Operator Dependency

Quality Control Delays Causing Production Bottlenecks

Limited Visibility and Traceability

Manufacturing Pain Points:

Defect Detection Accuracy

Reduction in Quality Control Labor Costs

Real-Time Visibility

and Alerts

What benefits can you expect?

Computer Vision Impact on Key Quality Dimensions

Our Computer Vision solution transforms quality control by automating visual inspections and enabling real-time defect detection. Here’s how it delivers value across critical areas of your production line.

Streamlining Visual Tasks with Automation

Our solution significantly reduces human intervention in repetitive and visual inspection tasks. By automating defect detection with real-time image analysis, it minimizes the risk of human error, ensures consistent quality, and frees up skilled operators for higher-value work. The result: fewer bottlenecks, faster throughput, and scalable operations.

Packaging Validation with Precision

Reducing Waste Through Early Detection

Computer Vision Use Cases

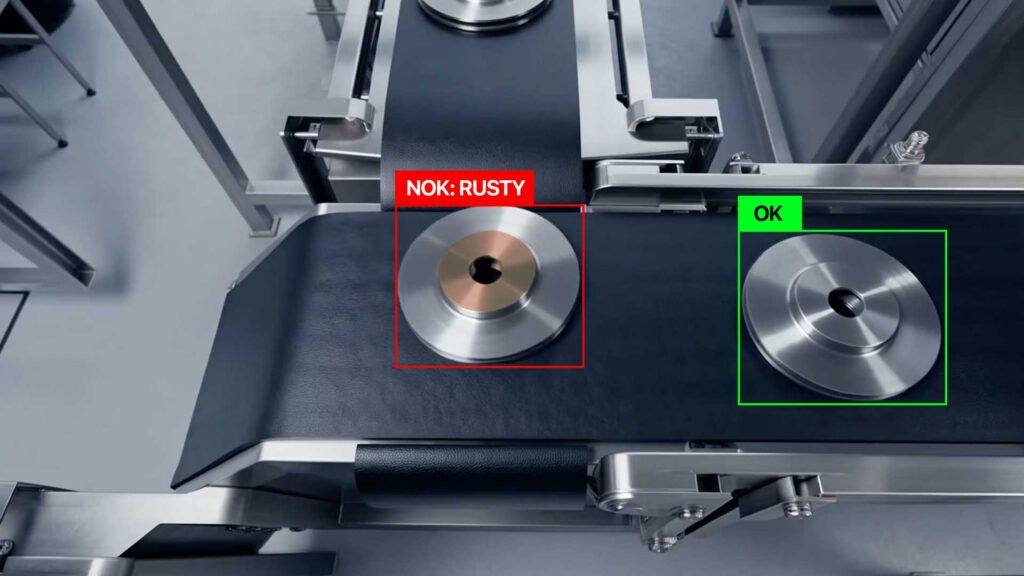

Global manufacturer of automotive components

Manual quality control automation for metal parts production.

The solution is an AI-powered dual-station vision system that inspects both sides of metal parts using top and side cameras, automatic flipping, and laser-triggered rejection. It includes a user-friendly interface for model selection, real-time monitoring, and retraining management.

Challenge

- Real-time inspection at a rate of 1 part per second, despite vibrations and random positioning on the conveyor.

- Multi-camera view correlation to inspect both sides and determine part conformity.

- Managing reflections on metal surfaces that conceal micro-defects: custom diffuse lighting to eliminate glare.

- Ensuring consistent inspection conditions for parts ranging from 5 cm to 500 cm in size.

- Integration with laser triggers and ejectors for automatic rejection of defective parts.

Benefits

- Reduces the quality control team from 4 operators to 1 per shift (a supervisor), resulting in a total reduction of 12 operators.

- Enables pass/fail decisions in under 1 second, matching the line speed.

- Reduces false rejections and waste by 40% through precise rule-based filtering.

- Eliminates subjectivity by replacing human judgment with consistent AI-driven decisions.

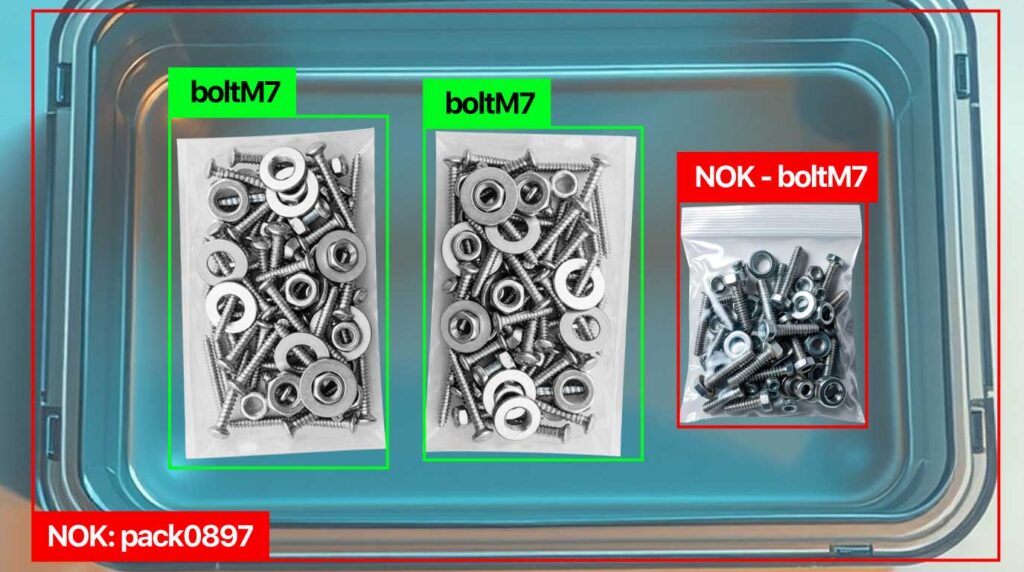

Multinational manufacturer of tools and fastening systems

Multimodal AI System for Automatic Package Content Verification

The solution is an AI-based vision system capable of verifying the contents of packages through real-time image and weight analysis. The system instantly adapts to unseen product references by training detection models on the fly, enabling reliable inspection within minutes—without interrupting production or requiring manual labeling.

Challenge

- On-the-fly Model Training Automation with Auto-labeling for New References, Without Interrupting Production Flow

- Real-time integration with cobots, weight sensors, and ERP systems for synchronized data capture and analysis.

- Ensure real-time availability of trained models on a dedicated station for immediate deployment across more than 10 Jetson-based verification stations.

- Guarantee speed, accuracy, and scalability in a high-variability environment where new product references are introduced daily.

Benefits

- Reduces inspection errors by over 90% thanks to dual-layer verification (vision + weight).

- Cuts SKU onboarding time from days to minutes through fully autonomous model training.

- Decreases rework and returns by up to 40%, improving product quality and reducing operational costs.

- Accelerates packaging cycles by 30% while maintaining output speed.

- Achieves full traceability through real-time ERP synchronization, supporting the company’s quality assurance process.

PET film manufacturer

Surface Defect Measurement and Classification

The solution is an AI-based vision system designed to detect, classify, and locate surface defects in real time. The system filters out tolerable anomalies, generates structured reports, and integrates with the MES to automatically create repair orders.

Challenge

- Integration with legacy vision systems that capture defect images but lack structured metadata or positioning information.

- Precise defect localization by correlating image timestamps with roller positions through external sources such as APIs.

- Minimization of false positives by filtering tolerable anomalies based on size, position, or type to avoid unnecessary repairs.

- Efficient image storage management, integration with existing NAS systems, and long-term data durability assurance (e.g., automatic cleanup of obsolete data).

Benefits

- Reduces operator workload by over 80%.

- Speeds up defect analysis time from minutes to seconds per image.

- Real-time MES integration enables instant repair order generation.

- Minimizes waste by 25% and focuses on critical issues.

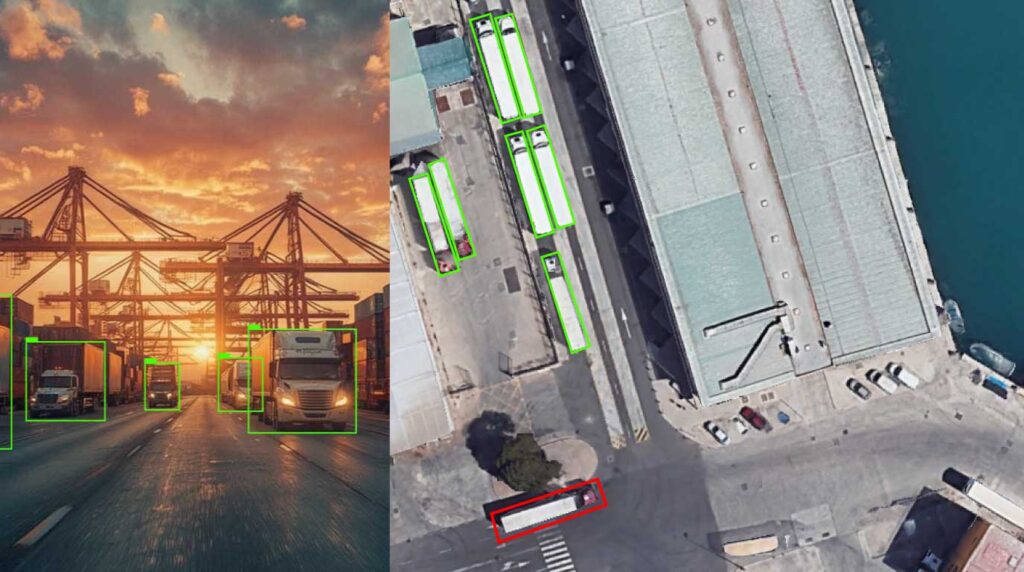

Port terminal operator

Real-Time Monitoring to Control Truck Access to Restricted Areas

The solution is an AI-based vision system that detects and tracks each truck across multiple camera zones, assigns it a consistent global ID, and visualizes its location on a zonal map in real time. The system integrates license plate recognition at key checkpoints, enables real-time monitoring, and is designed to scale across terminals with minimal infrastructure.

Challenge

- Continuous tracking of each vehicle across multiple zones despite occlusions, blind spots, or complex maneuvers (e.g., reversing, overtaking).

- Maintaining a consistent vehicle ID across more than 20 camera sources without duplication or loss during transitions.

- Integration of license plate recognition (LPR) and zone-based mapping ensures accurate location updates and access control at checkpoints.

- Real-time processing of large volumes of video data.

Benefits

- Replaces manual logging with continuous visual tracking of truck movements throughout the port.

- Reduces operator workload by eliminating manual checks and paperwork.

- Enables real-time visibility of all authorized forklifts, streamlining operational decision-making.

- Improves traceability through consistent vehicle ID tracking across all zones.

- Offers a scalable solution ready for over 20 camera streams and future terminal expansions.

Global manufacturer of electromagnetic components

AI-Based Microscopic Quality Inspection for Microcomponent Production

The solution is an edge-based computer vision system that automates the inspection of high-precision microcomponents, including critical elements such as windings and pins, which were previously inspected manually under microscopes. It detects small and complex defects in real time, ensuring consistent quality across all shifts and production lines without interrupting throughput.

Challenge

- Coordination of multi-camera captures (top and side views), identification, and correlation of part features across different images.

- Configurable defect tolerances, including the ability to ignore certain defects based on product or customer standards.

- Management of diverse inspection setups and frequent component changes across more than 10 production lines.

- Real-time AI-based inspections performed in under 2.5 seconds to match production cycle times.

- Integration with PLCs via a custom bidirectional protocol for synchronized operation.

Benefits

- Reduces labor costs by lowering the number of operators per shift across more than 10 lines, saving over 30 operators company-wide.

- Speeds up inspection cycles to <2.5 seconds per part, maintaining full line speed without compromising quality.

- Improves defect traceability and root cause detection, reducing scrap and rework costs by up to 25%.

- Standardizes quality control across all lines, minimizing shift-to-shift variability and operator bias.

- Reduces setup time for new stations thanks to a scalable architecture and compatibility with station-specific logic.

Electronic display manufacturer

AI-Powered Visual Inspection Automation for Electronic Device Testing

Tupl’s AI-based vision system automates the visual inspection of electronic displays during functional testing. Fully integrated with the existing Raspberry Pi infrastructure, it synchronizes image capture with test events and accurately verifies various screen outputs.

Challenge

- Screen image capture with precise synchronization, aligned with test button events via Raspberry Pi–Jetson communication.

- Handling of various screen types and test programs, each requiring specific image templates and pass/fail logic.

- Differentiation between expected patterns and actual output, including pixel shifts, color deviations, missing segments, or boot errors.

- Ensures inspection robustness under varying lighting conditions and screen refresh behaviors to avoid false positives/negatives.

Benefits

- Eliminates manual visual checks, reducing operator workload and inspection time.

- Improves consistency and reliability by eliminating human error.

- Enables accurate defect detection to enhance traceability and root cause analysis.

- Provides real-time pass/fail decisions at the test station.

Global Pharmaceutical Distributor

Intelligent Inspection System for Trays and Medicine Boxes

This AI-powered computer vision system automates quality control for pharmaceutical batches. It inspects trays for cleanliness and verifies that each medicine box has intact packaging, correct labels, and no damage. The system provides real-time monitoring, automatic alerts for issues, and a digital record for traceability and compliance.Challenge

- Real-time inspection of complete trays containing multiple boxes while maintaining dispatch speed.

- Variability in packaging sizes, colors, and materials (cardboard, plastic, blister packs).

- Detection of subtle defects such as misaligned labels, corner damages, or surface contamination.

- Ensuring stable inspection conditions despite artificial warehouse lighting and possible dirt accumulation on reusable trays.

- Integration with traceability systems and ERP to secure digital records of each batch.

Benefits

- Ensures compliance with pharmaceutical quality and safety regulations (GMP, GDP).

- Reduces the need for intensive manual inspection, freeing personnel for higher-value tasks.

- Minimizes human errors that may lead to returns, penalties, or loss of customer trust.

- Guarantees consistent deliveries to points of sale with products in perfect condition.

- Provides complete inspection traceability, facilitating both internal and external audits.

AI computer Vision For AI Quality Inspection

Frequently Asked Questions

What kind of defects can the AI Computer Vision detect?

Our AI Computer Vision system is designed to detect a wide range of surface and structural defects in real time across various manufacturing environments. It can identify issues such as:

- Scratches, dents, and cracks

- Surface irregularities or deformations

- Color inconsistencies or stains

- Missing or misaligned components

- Contamination or foreign objects

- Defective shapes or dimensions

Thanks to its high-resolution imaging and adaptable AI models, the system ensures over 99% defect detection accuracy. It’s fully retrainable, allowing it to adapt to new defect types and product variations without requiring coding expertise or changes to existing production lines.

Is the system compatible with our existing cameras and infrastructure?

Yes. The solution is designed for easy integration with most standard industrial cameras and PLCs. There’s no need to invest in specialized hardware.

Do we need AI experts or data scientists to use this solution?

No. The platform is completely no-code. Operators can upload images, label data, train models, and monitor predictions using an intuitive interface—no technical expertise required.

Can we scale the system across multiple lines or factories?

Absolutely. The solution supports centralized monitoring across multiple production lines, factories, and regions. It’s built for scale.

What accuracy can we expect?

You can expect >90% accuracy for defective part detection.

AI Computer Vision Beyond the Factory

Discover how our AI Computer Vision helps optimize not just production lines, but also agricultural yields.