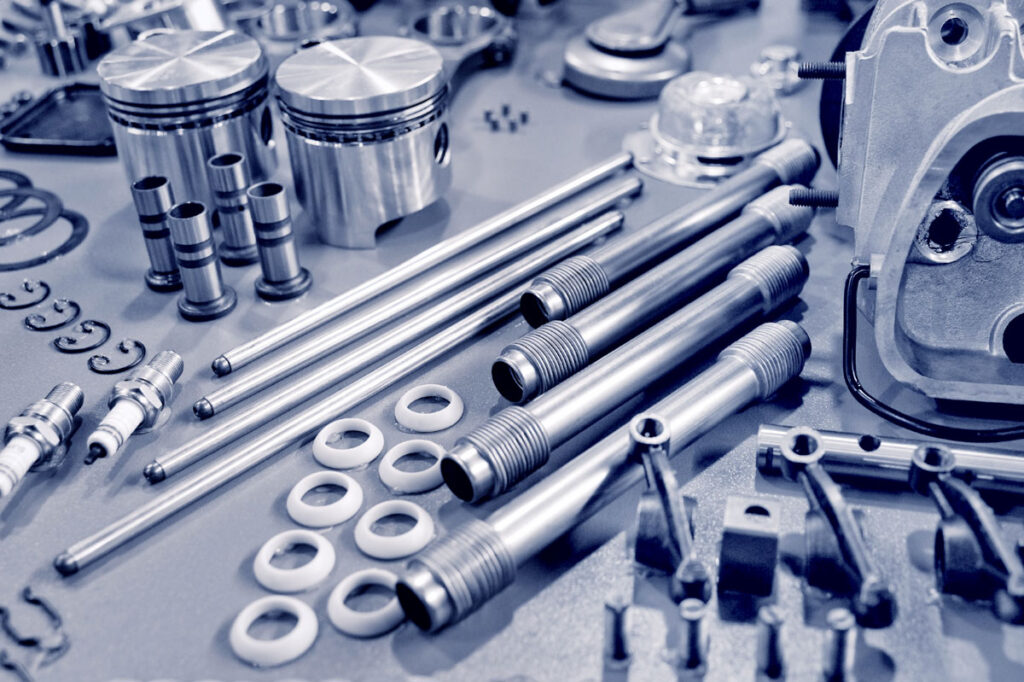

Use Case Global manufacturer of automotive components

With multiple high-volume production lines operating non-stop, the company aimed to fully automate the quality control process of its metal parts lines, with the goal of increasing productivity, eliminating manual labor, and maintaining the highest quality standards.

Automating Quality Control for Metal Parts

The company sought to eliminate manual inspection and implement a fully automated vision-based defect detection system on its metal parts lines. The ultimate goal was to fully remove human intervention in quality inspection while preparing the system for future enhancements, such as automatic side flipping and the arrangement of conforming parts.

Challenge

Manual Inspection Limits Scalability and Accuracy

- High line speed (1 part per second) with the need for real-time inspection and classification

- Random positioning of parts on the conveyor

- Elimination of human involvement while preserving accuracy

- Inconsistent detection due to operator fatigue

- Lighting, vibrations and variability in part placement complicating camera-based inspection

Solution

Vision AI-Based Inspection with Automated Defect Ejection

Tupl implemented an AI-powered vision system on Conveyor 2—the most stable section along the line for image capture. Two inspection stations were deployed, each equipped with top and side-view cameras to capture both faces of the part. Laser sensors were installed to manage part timing and activate a high-speed pneumatic piston for automatic rejection of defective pieces.

A user-friendly interface allowed real-time monitoring of inspection results, and the team was enabled to independently retrain models as new parts or defect types were introduced.

Outcome

- Reduced the quality control team from 4 operators to 1 per shift (a controller) — achieving a total reduction of 12 operators per line

- Achieved reliable, real-time detection of surface defects on both sides of each part without human intervention

- Prepared the system for future automation of part flipping and conforming part arrangement

- Delivered a scalable, intuitive, and fully retrainable system, empowering Doga’s team for long-term autonomy

Installed Components

- Industrial Cameras (x6): High-resolution cameras mounted at two inspection stations (top and side views) for full-surface image acquisition.

- Laser Sensors (x2): Installed to detect part presence and synchronize the timing of image capture and piston activation.

- Pneumatic Ejection Piston (x1): High-speed actuator for automatic removal of defective parts identified by the AI model.

- Industrial Jetson Edge Device (x1): Handles real-time image inference and communicates with the server for model updates.

- Central Server (Trainer): Manages model training and orchestration, enabling future retraining and system scalability.

- User Interface Display: Touchscreen display installed for operators to view system status, inspection results, and initiate retraining when needed.