AI Computer Vision brings visual intelligence to the heart of AgriFood operations.

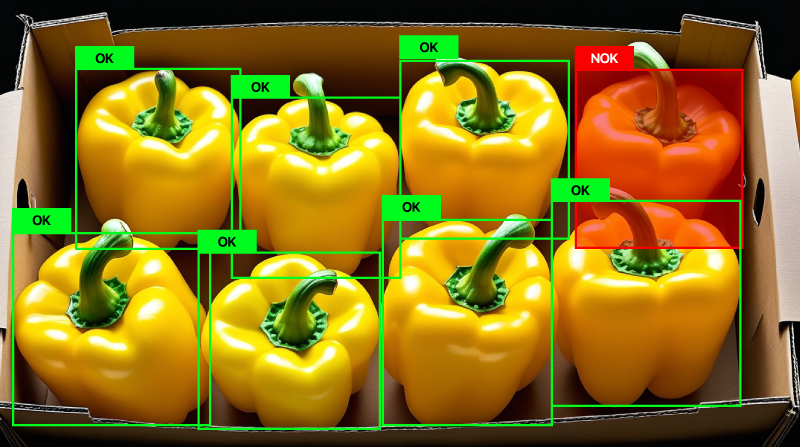

It monitors crop development, optimizes harvesting, detects defects in real time, and ensures traceability and flawless presentation in every package, helping agri-food companies make smarter decisions based on precise visual data.

By seamlessly integrating with ERP platforms, sensors, satellite imagery, and even advisory systems via WhatsApp, our solution simplifies harvest planning, resource management, and regulatory reporting.

AgriFood Pain Points:

Lack of Real-Time Crop Insight

Inefficient Use of Resources

(Water, Labor, and Materials)

Disconnected Systems

and Manual Reporting

Poor Planning and Limited Predictability

Human Error and Inconsistent Inspection

Defect Detection Accuracy

Reduction in Quality Control Labor Costs

Real-Time Visibility and Alerts

What benefits can you expect?

Optimizing AgriFood Quality with Computer Vision

Automating Quality Control in the Field and Factory

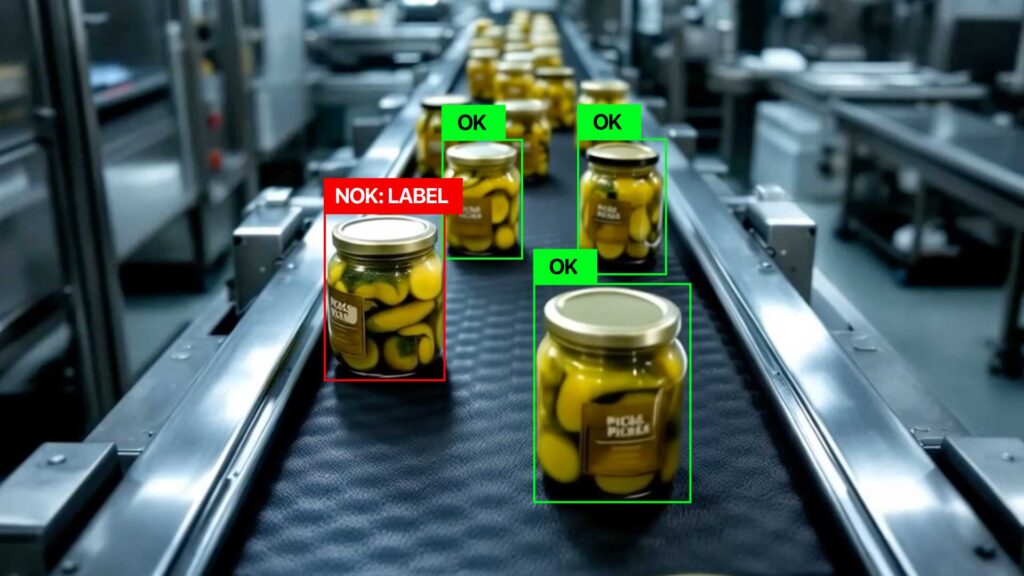

Compliance Secured Through Accurate Labeling

Cutting Food Waste with Real-Time Defect Detection

Computer Vision Use Cases

Preserved food manufacturer

Real-time defect detection in high-speed canning lines

The solution is a machine vision system for real-time detection of marking and filling defects across various types of containers, without interrupting production. It triggers automatic rejection within milliseconds and includes a touchscreen interface for model selection, alerts, and defect threshold configuration, fully integrated with existing factory systems.

Challenge

- Detection and rejection of defects in under 0.5 seconds per unit, ensuring real-time execution synchronized with actuators and conveyor belt speed.

- Integration with a PLC, under strict electrical and I/O constraints, while interfacing with sensors, alarms, and ERP systems.

- Training of accurate models (>90% accuracy) using limited, high-quality datasets across various defect types and container formats.

- Configuration of custom alarm logic allowing operators to set alarm thresholds, for example, triggering alerts after a defined number of consecutive defects.

Benefits

- Reduces operator workload related to inspection by 80%, minimizing manual intervention.

- Meets the accuracy threshold above 90%.

- Prevents quality issues from escalating through real-time alarms triggered by consecutive anomalies.

- Reduces false rejects and under-detected defects by 40%, improving product yield and consistency.

- Seamlessly adapts to different container types and formats, enabling scalability across production lines.

Large agricultural producer

Automation of Fruit Counting and Classification

The solution is a computer vision system based on mobile devices that automatically detects, counts, and classifies fruits according to their ripeness level using images taken with a smartphone. The solution enables reliable weekly yield estimates, facilitates real-time harvest planning, and reduces reliance on manual processes, offering scalable and highly accurate agricultural forecasts.

Challenge

- Automatic Detection and Classification of Fruits of Different Sizes, Colors, and Visibility Across Various Plant Types and Growth Stages

- Accurately count fruits from images without standardized backgrounds or fixed positions.

- Assign fruit counts to specific field zones and aggregate the results for weekly yield forecasts.

- Development of a mobile application to ensure a consistent image flow from on-field capture to cloud storage, enabling subsequent AI-based detection.

Benefits

- Forecast accuracy improves from ~75% to ≥95%, cutting estimation error in half.

- Field coverage efficiency increases fourfold (from 10 to 40 hectares per worker per day).

- Reduces manual workload and operator fatigue.

- Generates actionable outputs such as maturity and harvest estimation tables.

- Seamlessly integrates with SAP and agronomic platforms via API.

AI Computer Vision Solution for Smart AgriFood

Frequently Asked Questions

Which agrifood processes or stages can be identified and analyzed using AI-powered computer vision?

Do we need special cameras or hardware?

No. The solution is fully software-based and works with standard camera feeds or images captured via mobile, drone, or installed field cameras.

Can it integrate with our ERP or planning systems?

Yes. It’s built to integrate easily with agricultural ERPs and data platforms, allowing for automated synchronization of work orders, production records, and harvest planning.

How accurate is the detection?

The system delivers >90% precision in identifying crop stages and anomalies, ensuring data-driven decisions and efficient resource use.

How do farmers or field technicians interact with the system?

They can receive alerts and submit updates through WhatsApp or a mobile app, ensuring real-time communication without requiring new tools or technical skills.